In any modern industrial facility, the silent hum of efficiency is often orchestrated by a critical component: the Variable Frequency Drive (VFD). Often referred to as inverters or AC drives, a VFD is a sophisticated power conversion device. Its purpose is to precisely control the rotational speed and torque of an AC electric motor by manipulating the frequency and voltage of the power supplied to it.

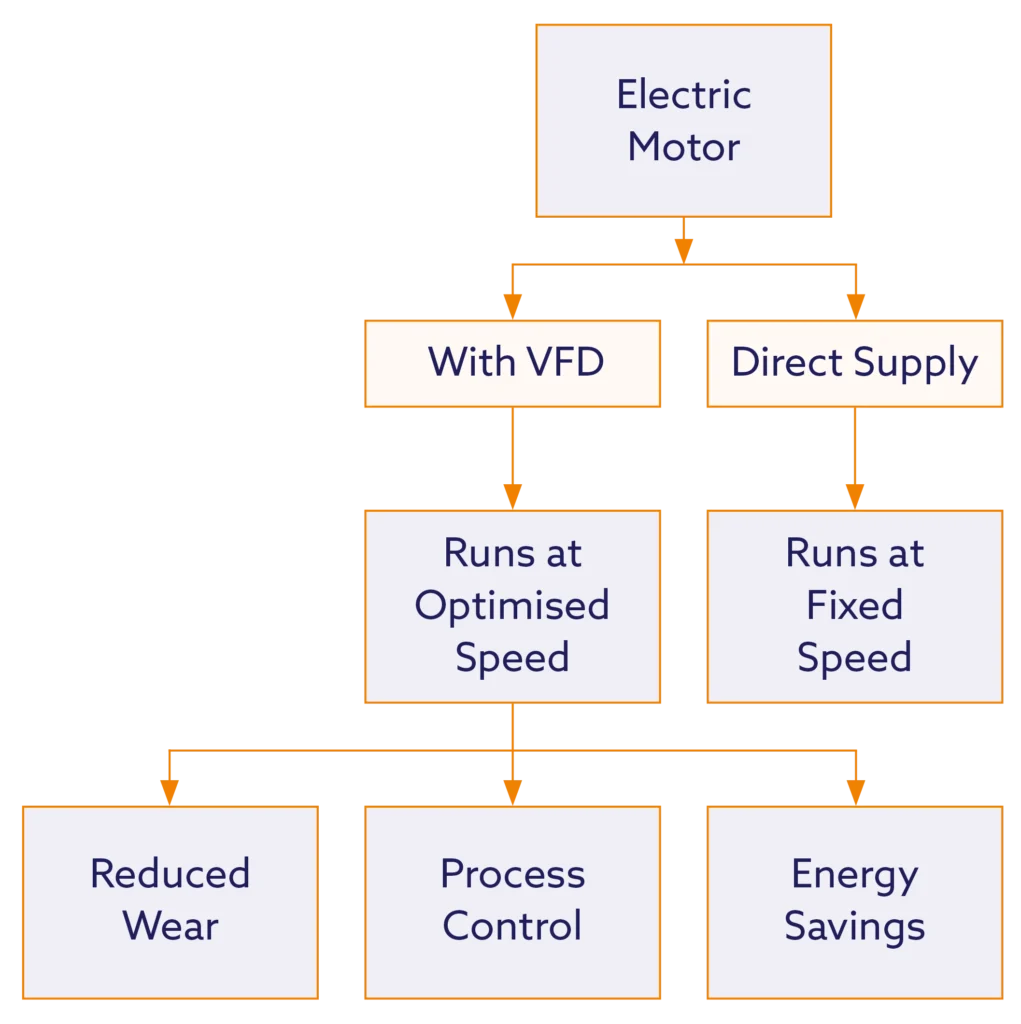

While a simple motor starter offers only a binary “on/off” control, a VFD provides a full spectrum of speed control. This capability has made them indispensable in applications across countless sectors.

VFDs deliver exceptional energy savings, particularly in variable torque applications such as centrifugal pumps, fans, and HVAC systems. By matching motor speed to actual load requirements rather than running at fixed speeds with throttling or damping, VFDs can reduce energy consumption by 20-50% in typical applications.

Modern manufacturing demands precise control over production parameters. VFDs enable smooth acceleration and deceleration profiles, eliminate mechanical shock loads, and provide infinitely variable speed control that optimises process conditions in real-time.

Soft-start capabilities eliminate the mechanical stress associated with across-the-line motor starting. This reduces wear on mechanical components including bearings, couplings, belts, and driven equipment, whilst simultaneously minimising electrical stress on motor windings and supply infrastructure.

By eliminating mechanical control devices such as throttling valves, inlet guide vanes, and mechanical speed control systems, VFDs reduce maintenance requirements whilst improving system reliability and availability.

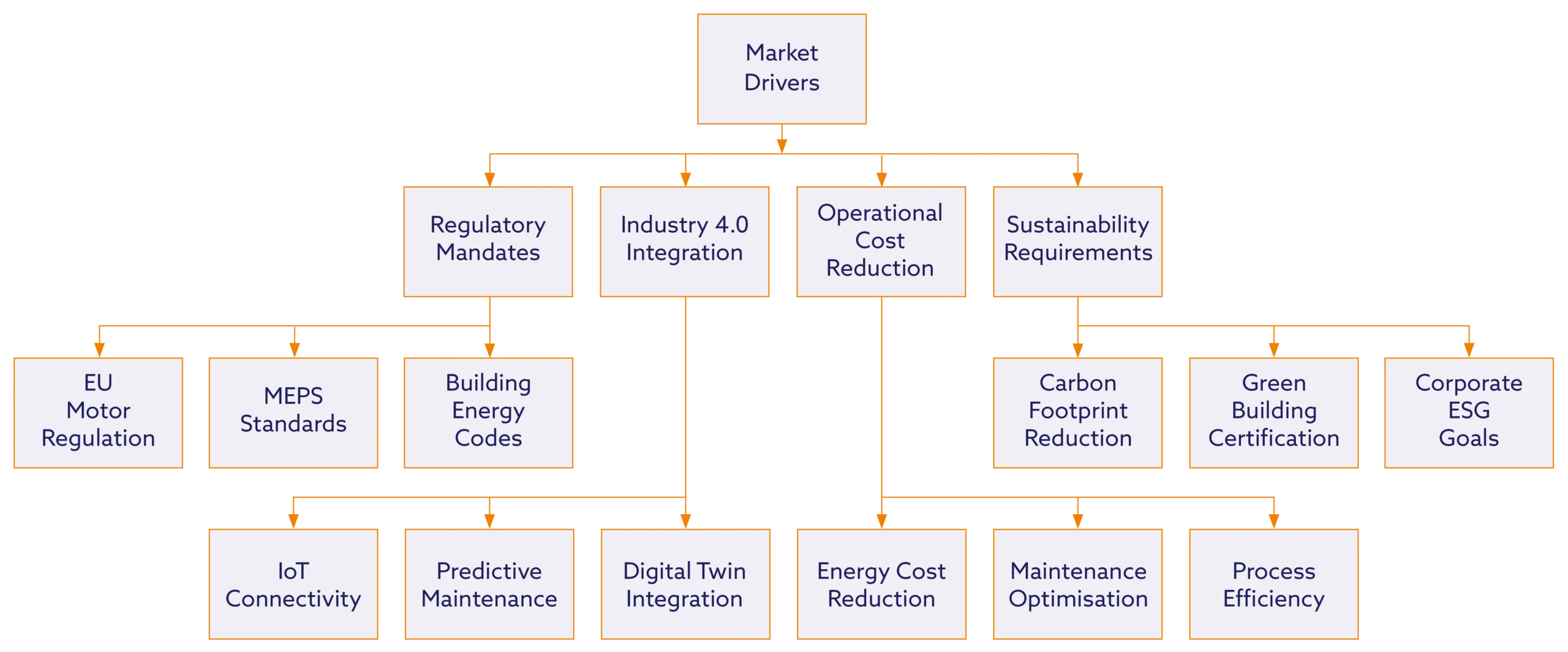

Energy efficiency regulations continue to tighten globally. The EU’s Motor Regulation mandates IE3 efficiency class motors for most applications, whilst building energy codes increasingly require variable speed control for HVAC systems. These regulatory frameworks make VFDs essential for compliance rather than optional upgrades.

The digital transformation of manufacturing has positioned VFDs as critical edge devices in smart factory architectures. Modern drives incorporate Ethernet connectivity, embedded web servers, and standardised communication protocols that enable seamless integration with SCADA systems, MES platforms, and cloud-based analytics services.

Rising energy costs and competitive pressures drive continuous focus on operational efficiency. VFDs provide measurable ROI through reduced energy consumption, lower maintenance costs, and improved process yields that directly impact profitability.

| Sector | Primary Applications | Growth Drivers |

|---|---|---|

| HVAC | AHUs, chillers, cooling towers, pumps | Building energy codes, comfort optimisation |

| Water/Wastewater | Pumps, bridge scrapers | Infrastructure modernisation, energy efficiency |

| Manufacturing | Conveyors, extruders, general processing equipment, mixers | Process optimisation, quality control |

| Oil & Gas | Pipeline pumps, compressors, drilling equipment | Operational efficiency, remote monitoring |

| Mining | Crushers, mills, conveyors, ventilation fans | Cost reduction, safety improvements |

| Marine | Propulsion systems, deck machinery, HVAC | Fuel efficiency, emissions compliance |

The global VFD market continues robust expansion, with compound annual growth rates exceeding 6% driven by widespread adoption across these core sectors. This growth reflects not just new installations, but also retrofit applications where VFDs replace legacy control systems to improve efficiency and capability.

As industrial facilities face increasing pressure to reduce energy consumption, improve process control, and integrate with digital systems, VFDs have evolved from specialised control devices to essential infrastructure components that enable competitive operation in modern markets.

In part 2 of this series, we will explain how VFD’s work and what the 3 core stages are.

VFDs have evolved beyond simple speed control. Today’s drives are smart systems that boost energy efficiency, enable precise automation, and connect seamlessly with modern factory networks.

1. Choose the right drive for your specific application and environment

2. Install it properly following best practices and safety standards

3. Maintain it well with regular checks and smart monitoring technology

We know that buying the right equipment is just the beginning. Our experienced engineers work with you at every step:

Selection: We help you choose the perfect drive for your needs

Installation: Our certified technicians ensure everything is set up correctly

Support: We provide ongoing maintenance and troubleshooting when you need it

Whether you’re building new systems, upgrading old equipment, or looking to cut energy costs, we have the drives and expertise to help. Our team stocks leading VFD brands and has the technical knowledge to make your project successful.

Contact Betech today and let us help you find the right drive solution for better performance, lower costs, and reliable operation.