Variable Frequency Drives have become indispensable in modern industry, transitioning from a niche technology to a foundational component for operational excellence.

Their ability to precisely control motor operation delivers a cascade of benefits that directly enhance energy efficiency, extend equipment lifespan, improve process quality, and contribute to sustainability goals.

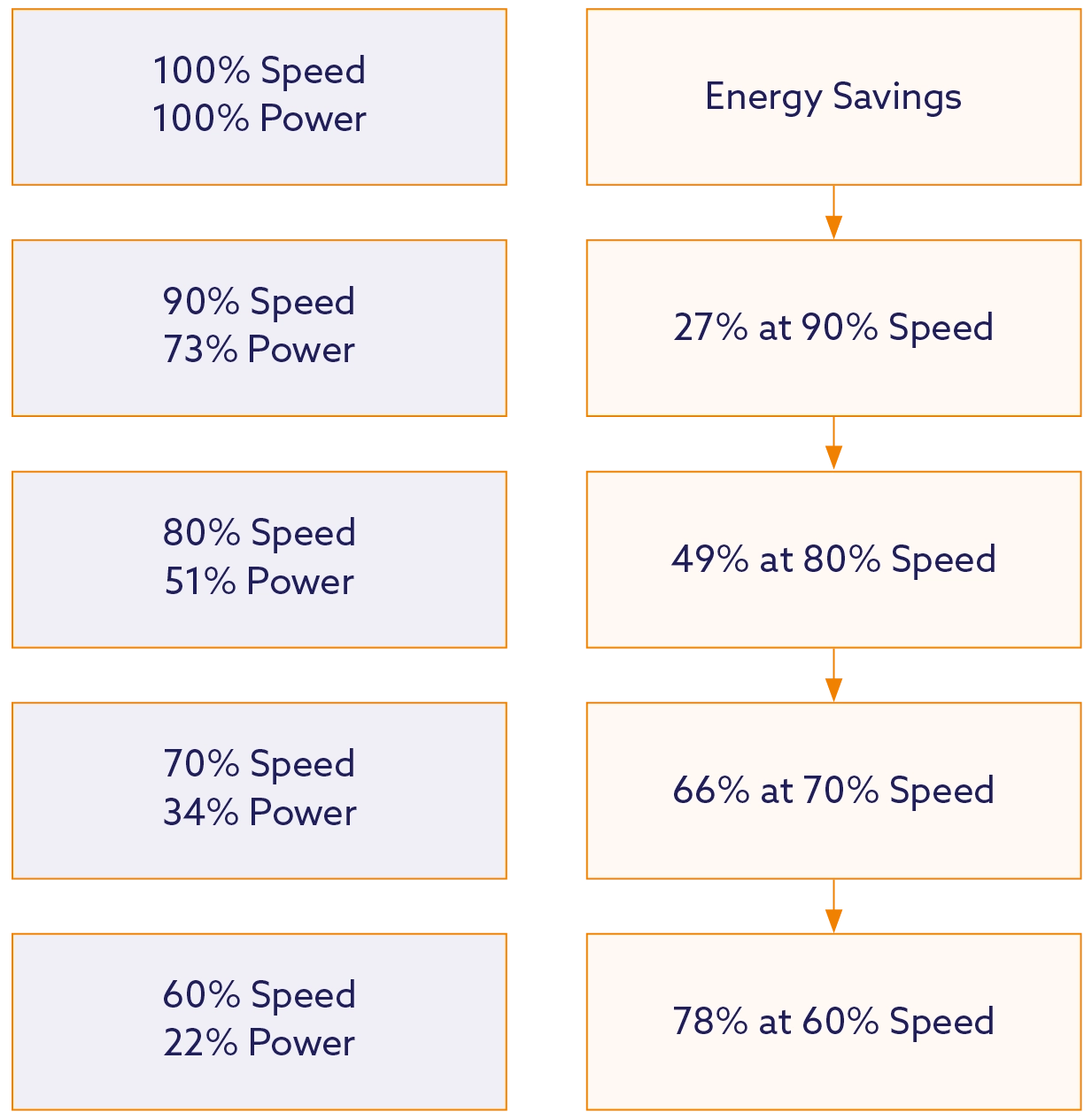

Perhaps the most widely recognised benefit of VFD technology lies in its capacity to significantly reduce energy consumption in variable torque applications such as centrifugal fans and pumps.

For centrifugal machines, the relationship between speed and power consumption follows cube law behaviour:

This means:

This cubic relationship means that even a small reduction in motor speed yields substantial energy savings. A 20% speed reduction can cut energy consumption by nearly 50%. In contrast, traditional methods like throttling valves or dampers force the motor to run at full speed while mechanically restricting the output—a process analogous to driving a car with the accelerator fully depressed while controlling speed with the brake.

| Application | Traditional Control | VFD Control | Energy Savings | Annual Cost Reduction* |

|---|---|---|---|---|

| HVAC Fan (100kW) | Damper control | Variable speed | 35-45% | £15,000-£19,000 |

| Cooling Tower Fan | On/off cycling | Continuous modulation | 25-40% | £11,000-£17,000 |

| Centrifugal Pump | Bypass/throttling | Speed matching | 20-50% | £9,000-£21,000 |

| Compressor | Load/unload | Variable capacity | 15-35% | £6,500-£15,000 |

*Based on £0.12/kWh, 8760 hours/year operation

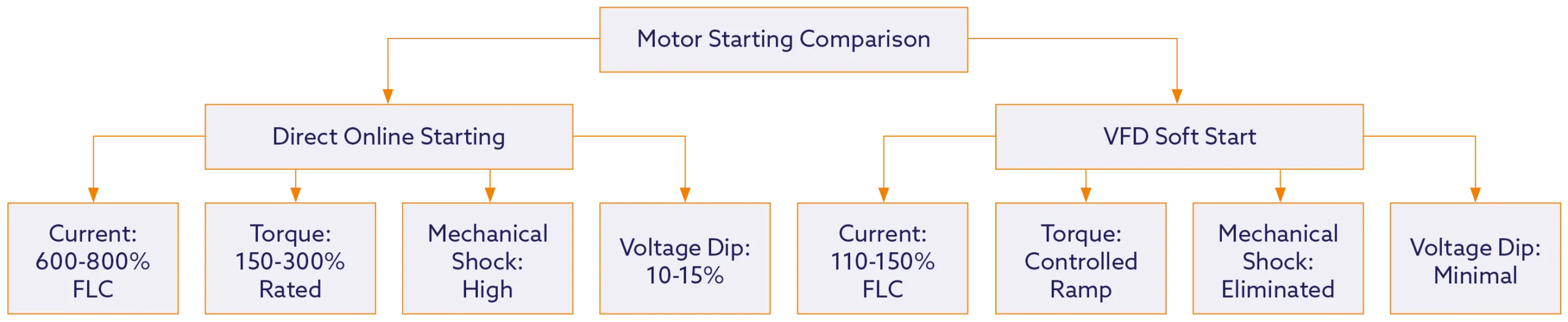

VFDs provide a controlled, gradual acceleration and deceleration of the motor, reducing mechanical stress on the entire system.

Traditional direct-on-line starting creates severe electrical transients:

VFD Soft Start Characteristics

The elimination of starting shocks provides substantial benefits for mechanical components:

| Component | Traditional Starting Impact | VFD Soft Start Benefit |

|---|---|---|

| Motor Bearings | High radial/axial forces | Extended life (2-3x typical) |

| Couplings | Shock loading, fatigue | Reduced wear, alignment stability |

| Belt Drives | Sudden tension spikes | Improved belt life, reduced slippage |

| Gearboxes | Impact loading | Reduced backlash wear, smoother operation |

| Driven Equipment | Mechanical shock | Protection of impellers, rotors, seals |

VFDs correct the poor power factor often associated with induction motor operation under varying load conditions.

This improvement reduces utility demand charges and improves overall electrical system efficiency.

| Operating Condition | Input Power Factor | Motor Power Factor | System Benefit |

|---|---|---|---|

| Full Load | 0.95-0.98 | 0.85-0.90 | Excellent correction |

| Partial Load | 0.92-0.96 | 0.70-0.85 | Good correction |

| Light Load | 0.85-0.92 | 0.50-0.70 | Significant improvement |

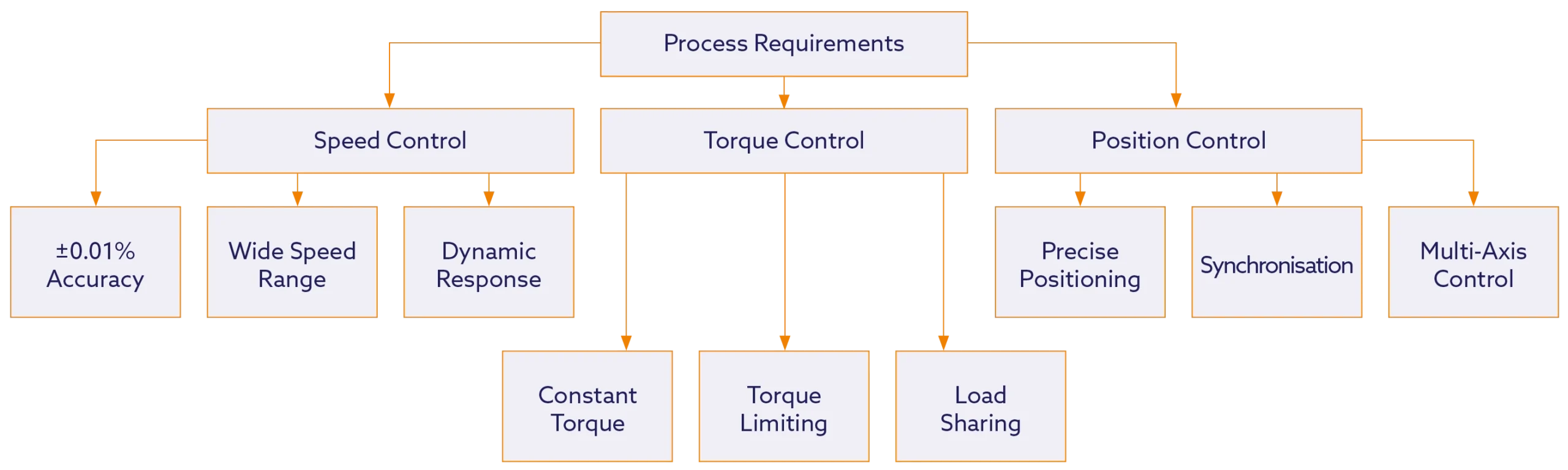

The precise speed and torque regulation delivered by VFDs allows processes to operate optimally under changing conditions, improving both quality and throughput.

In applications with overhauling loads (e.g., cranes, hoists, elevators, downhill conveyors), kinetic energy must be dissipated during braking. Standard VFDs dissipate this energy as heat through braking resistors. However, VFDs with Active Front End (AFE) technology can capture this energy and feed it back to the grid.

The operational advantages of VFDs translate directly into a smaller environmental footprint.

Energy efficiency improvements directly translate to reduced carbon emissions:

| Benefit Category | Key Outcomes | Typical Savings/Impact |

|---|---|---|

| Energy Efficiency | Reduced kWh consumption | 20–50% savings |

| Soft Start/Stop | Minimised electrical & mechanical stress | Longer asset life |

| Improved PF | Reduced utility penalties | 5–15% billing reduction |

| Process Control | Improved quality & throughput | Higher yield rates |

| Regenerative Braking | Energy fed back to grid | 10–30% recovery in applicable systems |

| Environmental Impact | Lower CO₂ emissions | Support ESG goals |

Next, in part 5 of our VFD series, we will look at the Key Selection Considerations for Variable Frequency Drives.

VFDs have evolved beyond simple speed control. Today’s drives are smart systems that boost energy efficiency, enable precise automation, and connect seamlessly with modern factory networks.

1. Choose the right drive for your specific application and environment

2. Install it properly following best practices and safety standards

3. Maintain it well with regular checks and smart monitoring technology

We know that buying the right equipment is just the beginning. Our experienced engineers work with you at every step:

Selection: We help you choose the perfect drive for your needs

Installation: Our certified technicians ensure everything is set up correctly

Support: We provide ongoing maintenance and troubleshooting when you need it

Whether you’re building new systems, upgrading old equipment, or looking to cut energy costs, we have the drives and expertise to help. Our team stocks leading VFD brands and has the technical knowledge to make your project successful.

Contact Betech today and let us help you find the right drive solution for better performance, lower costs, and reliable operation.