The control method, or algorithm, running on a VFD’s microprocessor dictates its performance characteristics, particularly its ability to regulate motor speed and torque. The choice of control method is a critical engineering decision, balancing application requirements for precision and dynamic response against system cost and complexity.

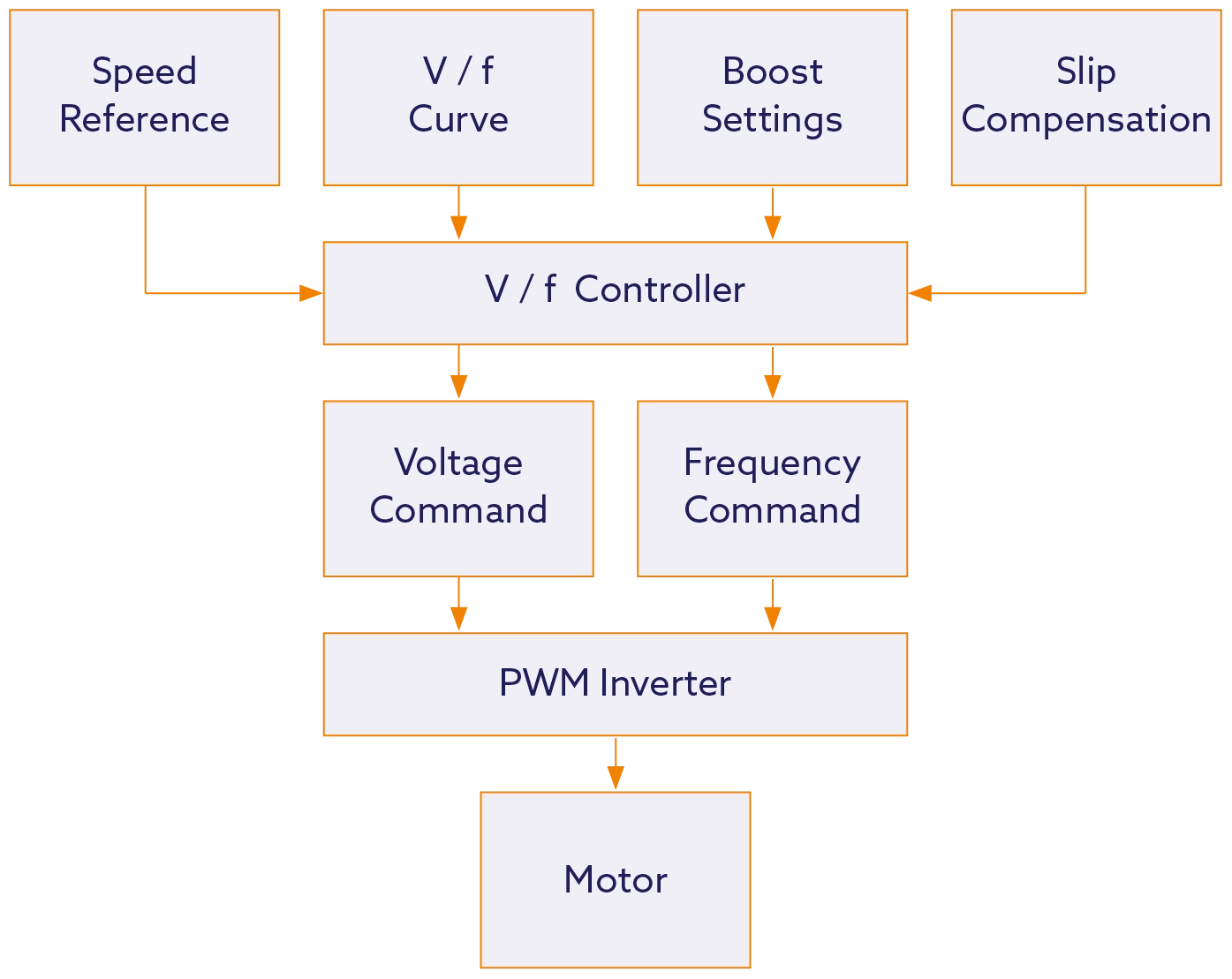

Voltage/Frequency control — often referred to as scalar control — maintains a constant ratio between output voltage and frequency to preserve motor flux. It is the simplest form of VFD control, ideal for applications where speed regulation requirements are modest and load torque characteristics are predictable.

V/f control operates on the fundamental relationship:

Ideal for variable torque loads where high precision is not required, such as centrifugal pumps, fans, and blowers. This method is the workhorse for achieving the significant energy savings in HVAC and fluid handling systems.

| Application Type | Benefits | Considerations |

|---|---|---|

| Centrifugal Fans | Energy savings, soft start | Speed droop under load acceptable |

| Centrifugal Pumps | Flow control, reduced wear | Pressure variations manageable |

| HVAC Systems | Comfort control, efficiency | Temperature control loops compensate |

| Simple Conveyors | Cost-effective speed control | Load variations cause speed changes |

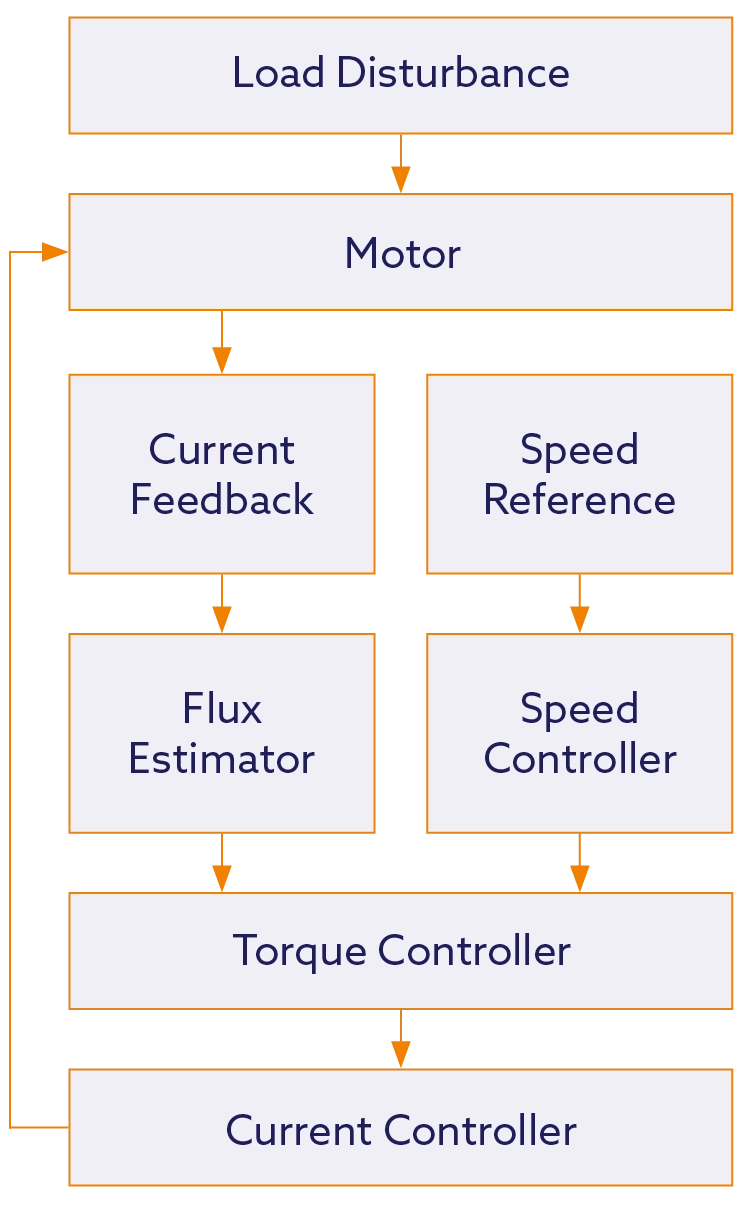

Sensorless vector control offers a significant performance improvement over scalar control without the need for an external feedback device.

SVC uses a sophisticated mathematical model of the motor embedded in the drive’s firmware. By measuring the output voltage and current, the drive can calculate and independently control the motor’s flux-producing and torque-producing current vectors. This allows it to estimate and compensate for motor slip, delivering much tighter speed regulation.

Sensorless vector control bridges the gap between basic V/f and high-performance closed-loop systems:

Conveyors, mixers, extruders, machine tools, and positive displacement pumps where consistent speed under varying loads is important for process efficiency.

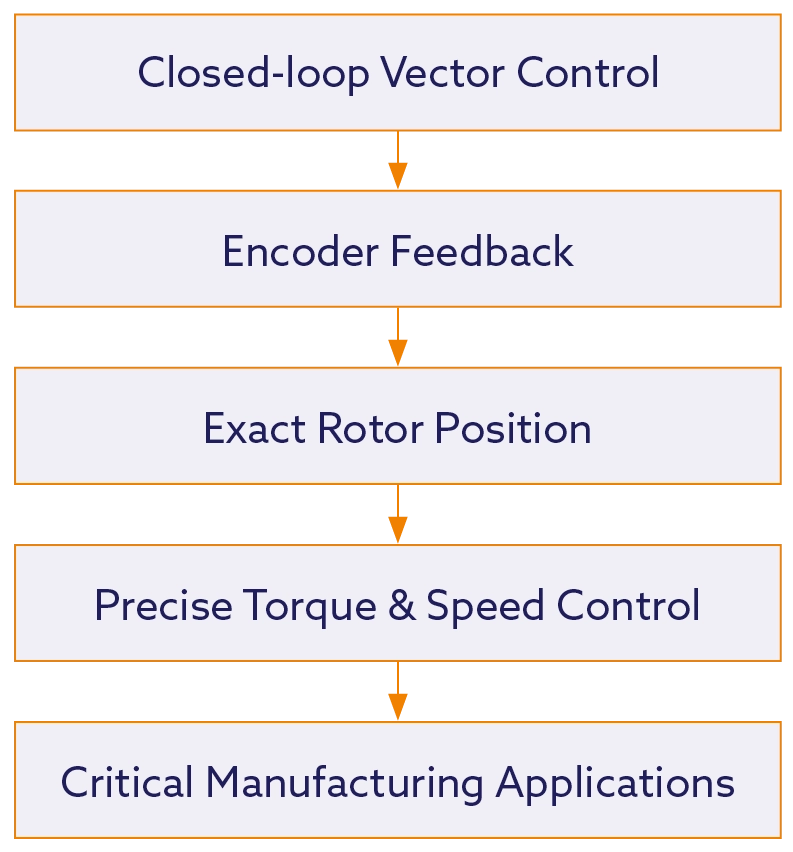

For the highest levels of precision, closed-loop vector control adds a physical feedback device to the system, providing the drive with exact information about the motor’s state.

This method builds upon the principles of SVC but incorporates real-time feedback from a motor shaft encoder or resolver. This feedback closes the control loop, allowing the VFD to know the motor’s exact speed and rotor position at all times. This eliminates estimation errors and enables precise torque and speed control down to zero speed.

High-performance systems requiring precise coordination or positioning, such as printing presses, web handling (winders/unwinders), cranes, hoists, and CNC spindles.

Direct Torque Control is a proprietary high-performance control strategy that offers the fastest possible torque response. It directly controls motor torque and flux through optimised switching patterns.

DTC eliminates the coordinate transformations required in FOC, enabling the fastest possible torque response.

Unlike vector control which focuses on manipulating current vectors, DTC directly controls the motor’s stator flux and electromagnetic torque. It uses an adaptive motor model and advanced hysteresis control to select the optimal IGBT switching state on a microsecond-by-microsecond basis to keep the flux and torque within defined bands.

The most demanding industrial applications, including rolling mills, high-speed winders, cross-cutters, and test dynamometers.

| Aspect | DTC | FOC |

|---|---|---|

| Response Time | Ultra-fast (<1ms) | Fast (1-5ms) |

| Switching | Direct switching | PWM modulation |

| Parameter | Less sensitive | More sensitive |

| Complexity | Higher | Moderate |

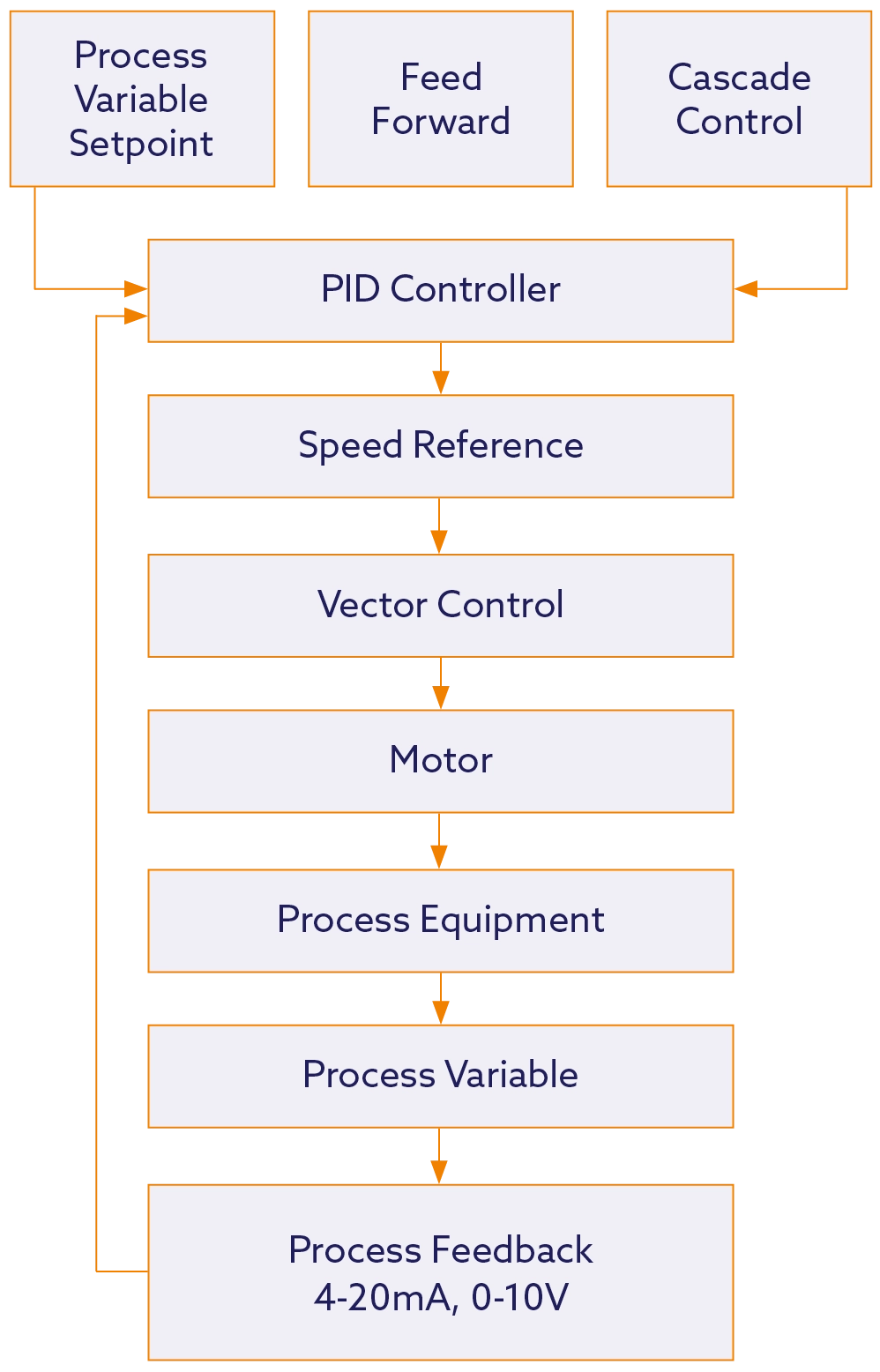

Modern VFDs increasingly incorporate sophisticated process control capabilities, enabling direct regulation of process variables such as pressure, flow, temperature, or level without external controllers.

The VFD includes a built-in Proportional-Integral-Derivative (PID) controller. It can receive a process feedback signal (e.g., from a pressure, flow, or temperature transmitter) and compare it to a desired setpoint. The PID logic then automatically adjusts the motor speed to eliminate the error and maintain the process variable at the setpoint, removing the need for an external PLC for simple loop control.

| Process Variable | Application | Control Benefits |

|---|---|---|

| Pressure | Booster pumps, compressors | Constant pressure regardless of demand |

| Flow | Chemical dosing, water treatment | Precise flow control with energy optimisation |

| Temperature | HVAC, process heating | Integrated motor and process control |

| Level | Tank filling, batch processes | Automated level maintenance |

Choosing the appropriate control method requires careful consideration of application requirements, performance specifications, and cost constraints:

Performance Hierarchy

| Requirement | V/f | Sensorless Vector | Closed-Loop Vector | DTC |

|---|---|---|---|---|

| Speed Accuracy | ±3-5% | ±0.5-1% | ±0.01-0.1% | ±0.01-0.1% |

| Torque Response | Slow | Fast | Very Fast | Ultra-Fast |

| Starting Torque | 150% | 200% | 200% | 200% |

| Speed Range | 20:1 | 1000:1 | 10,000:1 | 10,000:1 |

| Cost | Low | Medium | High | High |

| Complexity | Simple | Medium | Complex | Medium |

In practical implementation, many industrial VFDs support multiple control modes selectable via configuration, allowing flexibility to match application requirements and adapt to evolving process demands.

In part 4 of our VFD series, we will look at the benefits of VFD implementation.

VFDs have evolved beyond simple speed control. Today’s drives are smart systems that boost energy efficiency, enable precise automation, and connect seamlessly with modern factory networks.

1. Choose the right drive for your specific application and environment

2. Install it properly following best practices and safety standards

3. Maintain it well with regular checks and smart monitoring technology

We know that buying the right equipment is just the beginning. Our experienced engineers work with you at every step:

Selection: We help you choose the perfect drive for your needs

Installation: Our certified technicians ensure everything is set up correctly

Support: We provide ongoing maintenance and troubleshooting when you need it

Whether you’re building new systems, upgrading old equipment, or looking to cut energy costs, we have the drives and expertise to help. Our team stocks leading VFD brands and has the technical knowledge to make your project successful.

Contact Betech today and let us help you find the right drive solution for better performance, lower costs, and reliable operation.