Gearboxes are crucial components in various industries, as they transmit mechanical power and torque from one rotating part to another. They come in different types, such as bevel, helical, and worm gearboxes. In this article, we'll discuss how each of these gearboxes works, their efficiency, advantages, disadvantages, and applications in different industries.

The main difference between bevel and helical gears lies in their tooth geometry and the way they transmit power. Bevel gears have teeth cut along a conical surface and transmit power between intersecting shafts, while helical gears have teeth cut at an angle to the gear axis and can transmit power between parallel or non-parallel shafts.

Yes, helical gears are generally more efficient than worm gears due to their tooth geometry, which allows for greater tooth contact, smoother engagement, and reduced friction during operation.

Yes, worm gears can change the direction of rotation, similar to bevel gears. The direction of rotation of the output shaft (worm wheel) will be opposite to that of the input shaft (worm gear) in a worm gearbox.

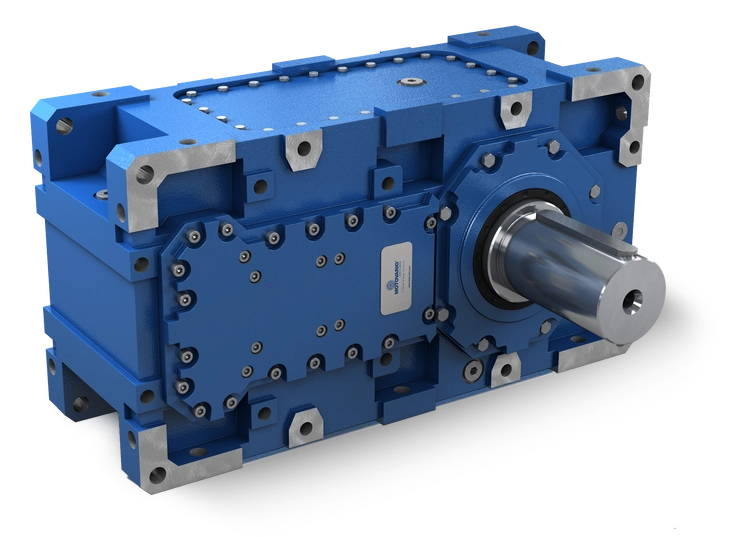

Helical gearboxes are commonly used in various industries, such as automotive, aerospace, food processing, material handling, and heavy machinery, among others. Their high efficiency, smooth operation, and ability to transmit power between non-parallel shafts make them suitable for a wide range of applications.

Worm gearboxes are generally not suitable for high-speed applications due to their lower efficiency and higher friction compared to other types of gearboxes. However, they can be used in applications that require high torque transmission and a compact design at lower speeds.