Gearboxes are crucial components in various industries, as they transmit mechanical power and torque from one rotating part to another. They come in different types, such as bevel, helical, and worm gearboxes. In this article, we'll discuss how each of these gearboxes works, their efficiency, advantages, disadvantages, and applications in different industries.

Gearboxes are crucial components in various industries, as they transmit mechanical power and torque from one rotating part to another. They come in different types, such as bevel, helical, and worm gearboxes. In this article, we’ll discuss how each of these gearboxes works, their efficiency, advantages, disadvantages, and applications in different industries.

Bevel gearboxes are generally very efficient, with efficiency ratings typically ranging from 93% to 97%. The efficiency of a bevel gearbox depends on factors such as gear material, tooth profile, lubrication, and manufacturing quality. High-quality bevel gearboxes can provide smooth and efficient power transmission in various applications.

Bevel gearboxes are found in various industries, such as quarrying/aggregates, process controls & materials handling. Their high efficiency, smooth & operation, make them suitable for a wide range of power transmission applications.

There are three main types of bevel gears: straight bevel gears, spiral bevel gears, and hypoid bevel gears. Straight bevel gears have teeth cut straight and parallel to the gear axis, while spiral bevel gears have teeth that are curved and gradually increase in size from the large end to the small end. Hypoid bevel gears are a variation of the spiral bevel gear, with the gear axis offset, allowing for greater tooth contact and load-carrying capacity.

Bevel gears offer several advantages, such as smooth operation, high torque transmission, and the ability to change the direction of rotation. However, they also have some disadvantages, such as increased complexity in manufacturing and higher costs compared to other types of gears.

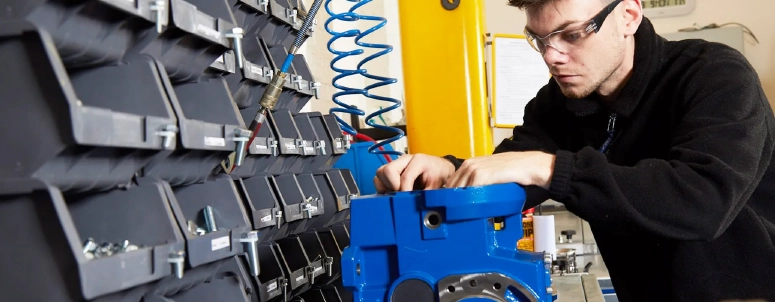

Motovario Assembly Centre the home for 1000s of Motovario geared motor selections available from stock